Description

Overview:

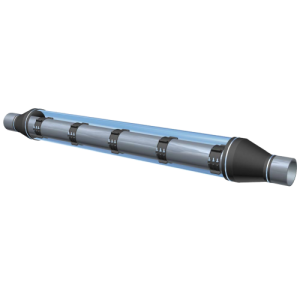

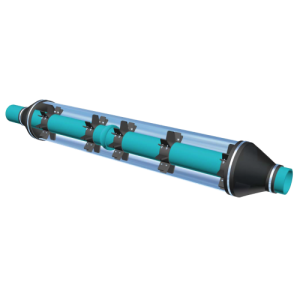

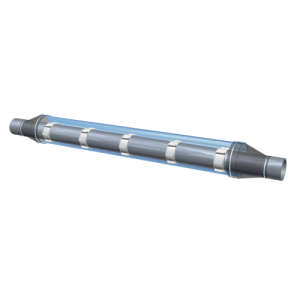

The Ranger II is an all non-metallic casing isolator/spacer system that uses moulded segments to encircle the carrier pipe. Each segment includes at least one moulded-in runner and one slide lock. Customers may choose from any one of five different size bands to allow correct sizing for carrier pipe O.D. ranges from 0.83 inches (21.1mm) up to 37.60 inches (95.5cm) in diameter. Once sized, the segments are placed around the carrier pipe and cinched together via non-metallic slide locks.

Installation is quick and easy while only a small inventory of segments may be used to accommodate a large variety of pipe styles, types and diameters.

Features:

- All non-metallic. No nuts, bolts, washers or any other metal parts to corrode or degrade over time.

- Designed for carrier pipe diameters from 0.83 inches (21mm) to 37.60 inches (955mm) in diameter.

- Segmented pieces – small inventory may be used to accommodate a large variety of pipe styles, types and diameters. No extra trips from job site to warehouse for additional parts.

- Easy assembly. Simply slide the segments together and cinch tight with the patented Slide-Lock connecting system.

- Wide variety of runner heights to allow numerous options for pipe positioning within the casing.

- Runner variations may be used to adjust for grade.

- Will accommodate small conduit attachment for communications or electrical cable.

- Medi and Maxi segments, 2 molded runners per segment.

- Segment band and runners molded as one piece.

- Manufactured from UV resistant polypropylene.

- High impact strength, 1.5 ft. lbs./inch (0.8 joules/cm)

- Excellent compressive strength, 3,000 psi (211 kg/square cm)

- 800 Volts/Mil. Dielectric Strength.

- Wide temperature range, -22 to 212 F. (-30 to 100 C.)

- Eliminates sand or grout fill.

- No special tools required for installation.

- Low coefficient of friction for ease of installation.

All Ranger II Casing Spacers require more than one segment to complete a spacer. In addition, all Ranger II Casing Spacers are available with a number of different runner height options which are used to guarantee clearance of the mechanical joint, provide for options in carrier pipe positioning within the casing or to compensate for grade elevation adjustments.